Introduction

Titanium forging is a specialized manufacturing process that transforms raw titanium into high-strength, lightweight components. Known for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium is forged for demanding applications in aerospace, medical, marine, and high-performance industrial sectors. This article explores the process, advantages, applications, and key considerations of titanium forging in detail.

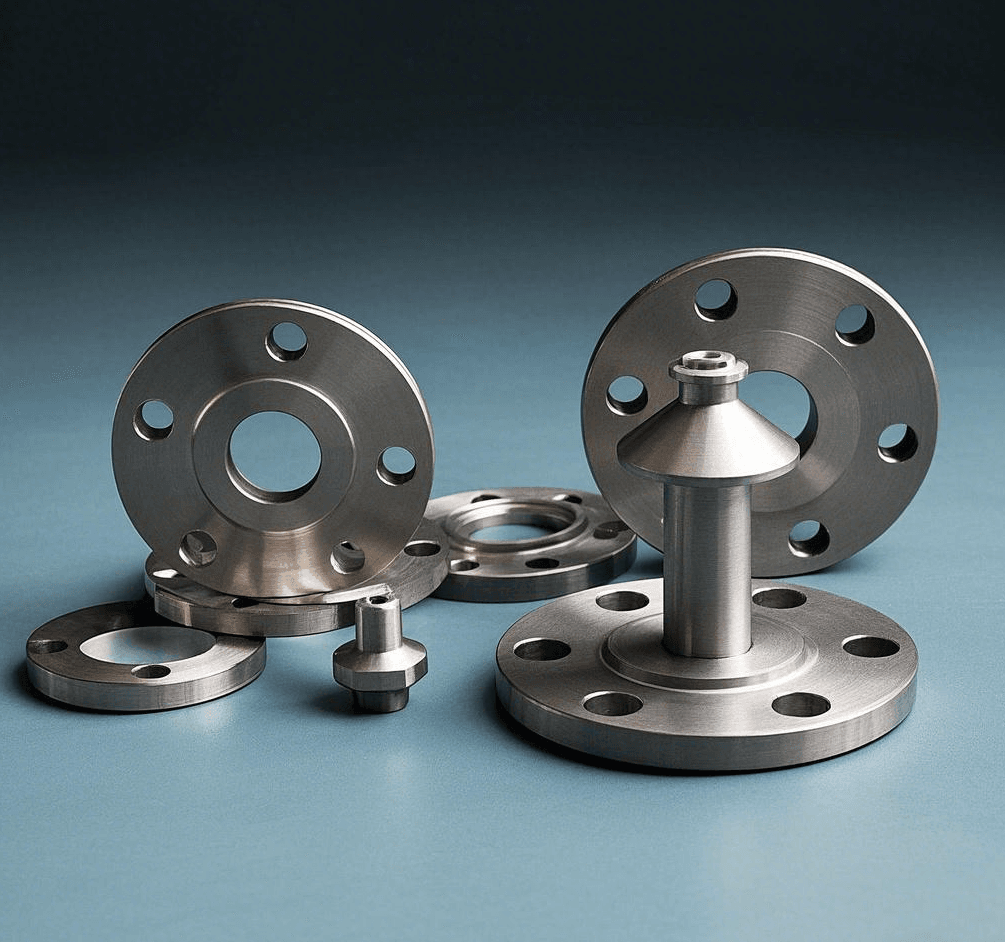

What is Titanium Forging?

Titanium forging involves shaping titanium under high pressure and temperature using compressive forces. Forging aligns the metal’s grain structure, enhancing its mechanical properties. Compared to casting or machining, forging titanium improves strength, fatigue resistance, and overall durability.Titanium, especially in its most common alloy forms such as Ti-6Al-4V, is challenging to machine and expensive to waste, making forging a preferred method to create near-net-shape parts efficiently and economically.

Advantages of Titanium Forging

1. Exceptional Strength-to-Weight Ratio

Titanium is as strong as steel but nearly 45% lighter, making forged titanium ideal for aerospace, motorsports, and military applications where weight savings are critical.2. Superior Corrosion Resistance

Forged titanium resists corrosion from seawater, acids, and chlorides, making it suitable for marine, chemical, and offshore environments.3. Excellent Fatigue and Impact Resistance

Forging refines the internal grain flow of titanium, greatly increasing its fatigue strength and impact toughness under cyclic or sudden loads.4. High Temperature Resistance

Titanium retains strength even at elevated temperatures, which is essential for jet engines and high-speed aerospace parts.5. Biocompatibility

Titanium is non-toxic and compatible with the human body, making it ideal for medical implants and surgical instruments.Grades and Alloys of Titanium Used in Forging

Several titanium grades are used in forging, with each suited to specific applications:Grade 2 (Commercially Pure Titanium): Offers good strength and excellent corrosion resistance. Common in marine and chemical processing.

Grade 5 (Ti-6Al-4V): The most widely used alloy; strong, heat-resistant, and ideal for aerospace and medical components.

Grade 23 (Ti-6Al-4V ELI): A purer version of Grade 5, used in biomedical applications.

Beta Alloys (e.g., Ti-10V-2Fe-3Al): Heat-treatable for extremely high strength, used in aerospace landing gear and high-stress components.

Types of Titanium Forging Processes

1. Open Die Forging

This process involves compressing the titanium between flat or contoured dies to form large parts such as bars, blocks, and discs. Ideal for custom or heavy-duty aerospace parts.2. Closed Die Forging (Impression Die)

Titanium is shaped within pre-formed dies, producing precise and complex shapes. This method minimizes material waste and is used for high-volume production.3. Isothermal Forging

In this advanced method, both the die and titanium are heated to nearly the same temperature to reduce strain and improve surface finish. Common in aerospace and medical part production.4. Hot Die Forging

Here, dies are kept at elevated temperatures, allowing titanium to flow more easily into intricate shapes. It reduces cracking and enhances metallurgical properties.Applications of Titanium Forging

1. Aerospace Industry

Titanium forging is vital in aerospace for parts such as turbine blades, fan disks, landing gear, structural brackets, and airframe components due to its light weight and high strength.2. Medical Sector

Implants such as hip joints, bone screws, dental implants, and surgical tools are forged from medical-grade titanium for superior compatibility and strength.3. Marine Industry

Titanium forged parts like propeller shafts, valves, and seawater piping systems are used in submarines and offshore platforms for long-lasting performance in harsh environments.4. Automotive and Motorsports

In racing and high-performance vehicles, titanium forged components like connecting rods, valves, and suspension parts reduce weight while increasing durability.5. Chemical Processing

Forged titanium fittings, reactors, and heat exchangers are used where resistance to corrosive chemicals is required.Challenges in Titanium Forging

High Cost: Titanium is expensive, and its forging requires specialized equipment and energy-intensive processes.

Tooling Wear: Titanium’s hardness and toughness wear out forging tools faster than other metals.

Narrow Forging Temperature Range: Titanium must be forged within a tight temperature range (typically between 900°C–1100°C) to prevent cracking or grain growth.

Oxidation: Titanium easily oxidizes at high temperatures, requiring inert atmospheres or protective coatings during forging.

Post-Forging Treatments

To enhance properties and achieve final dimensions, titanium forged parts often undergo:Heat Treatment: Annealing or aging to relieve stress and optimize strength.

Machining: Precision cutting or turning to achieve exact specifications.

Surface Finishing: Sandblasting, polishing, or passivation to improve surface quality and remove oxidation.

Inspection: Ultrasonic, X-ray, and dye penetrant testing to ensure part integrity.